15 Feb Engineering and Procurement Level of Detail

To develop a reliable Engineering schedule, the Planner has to have a good knowledge about:

- Relationships among Engineering deliverables

- Relationships among the disciplines

- Relationships between Engineering and Procurement

- Relationship between procurement and 3D model development

- Relationship between Engineering and Construction,

- Assist the team in man-hour estimation

- Provide guidelines in managing the reworks and revisions

- And many more

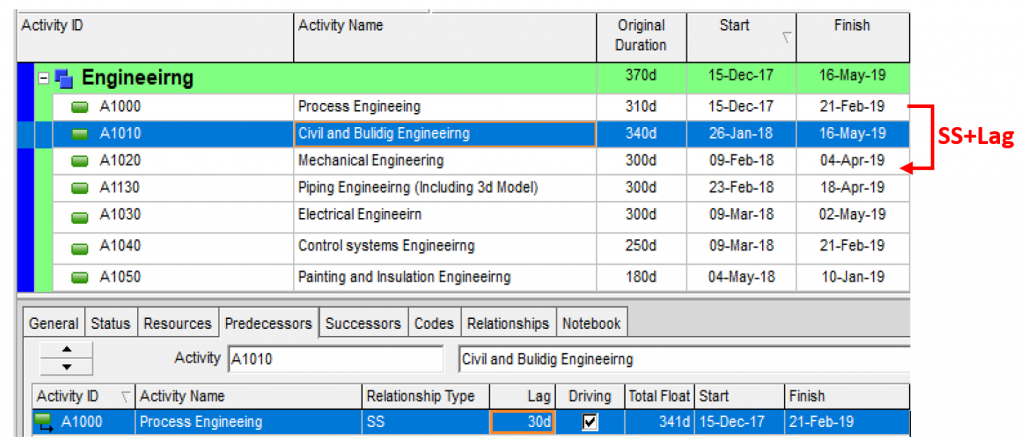

Majority of Planners do not have such knowledge and experience; therefore, they fail to support the Projects effectively. On certain cases, the Planner applies tricks and develops the Engineering and Procurement on a much higher level than Construction. As a result, he/she uses a lot of Start to Start + Lag in the logic.

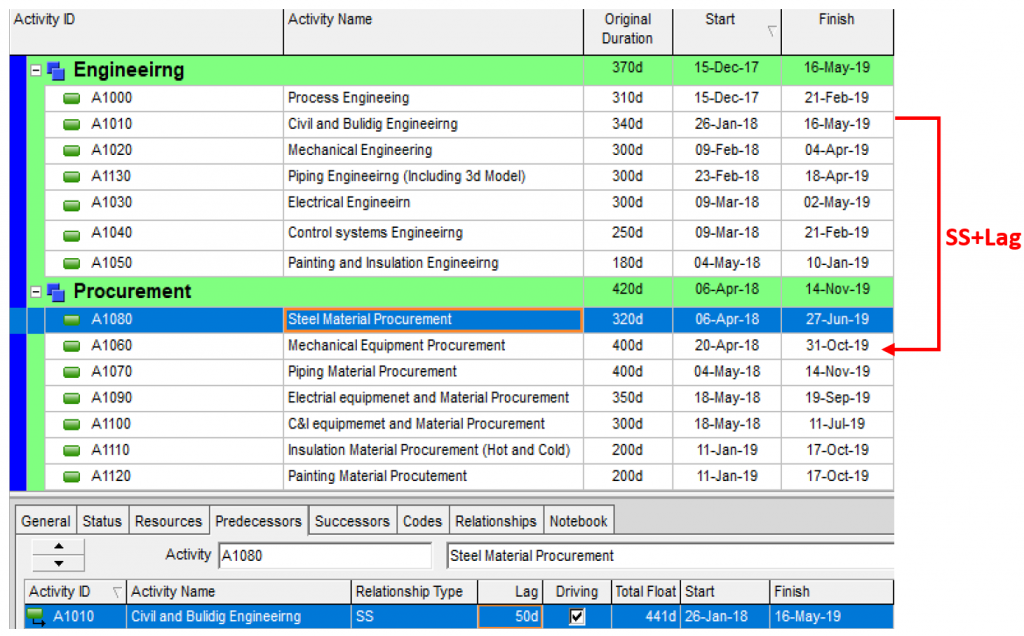

A similar methodology gets applied on Procurement activities and relationships with Engineering:

The same logics gets applied to relationship between Engineering and Construction and Procurement and Construction!

So:

- What is the bases for the amount of Lag? No base and the planner just adds in order to have different dates for activities!

- The Engineering and Procurement S-Curves will be a few straight lines or entirely incorrect!

- Analysis of the Engineering and/or Procurement delay in a Project will not be possible!

- The Project will have drama/ surprise the majority team members to not know about the delays in Engineering and Procurement until the last minute!

- Engineering resource management, risk management will not be possible!

- If the Schedule gets used to monitor the progress then, most likely, the progress reports would be incorrect!

During the schedule update, the Planner continuously changes the lag to keep the project finish date unchanged! Then after a while when the project experiences delays and the Schedule fails to support, it loses its credibility!

The failure of such project would be a direct result of the schedule and the planning system!

If you are running an EPC project, then contact us to:

- Conduct a gap analysis

- Prepare a comprehensive report from the finding

- Implement a planning system that supports the project

- Save time and money

info@khonopc.com

No Comments