07 Dec How important is Progress Report?

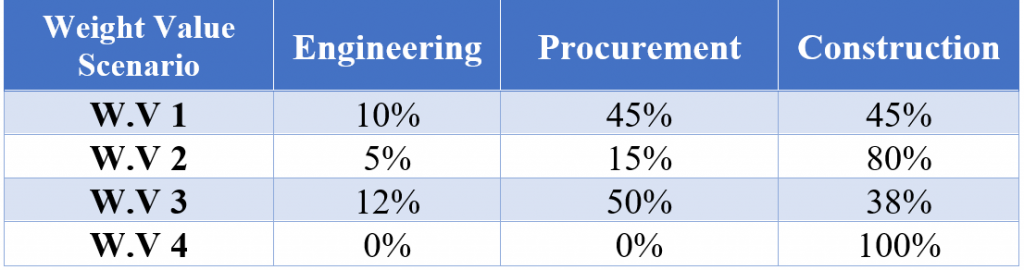

Discussions around progress reports and weight values never cease to exist. On almost every occasion, there will be another aspect (rightly or wrongly) to argue about. The argument becomes tense especially in EPC Projects around the weight values. Some of these arguments could as follows:

- If we complete Engineering (10%) and Procurement (40%) only, how can the overall project be 50% whilst construction is zero?

- What is the basis of calculations? Money, time, quantity, milestone, etc.? Whichever you chose, another one will be picked for argument!

- The progress report indicates the project is 98%, 99% complete but still cannot be used as final product. So, these numbers mean nothing. Tell us when it will be commercially ready for operation!

- Reporting on Engineering and Procurement adds no value, only focus of the construction!

- The progress report misleads because it does not show the critical paths? (or issues and concerns)

- The progress report depicts only a good picture for top management.

- And many more

Regardless of all the arguments, the progress reports are one of the most used reports in the Projects and the planning team updates and issue them every week/month.

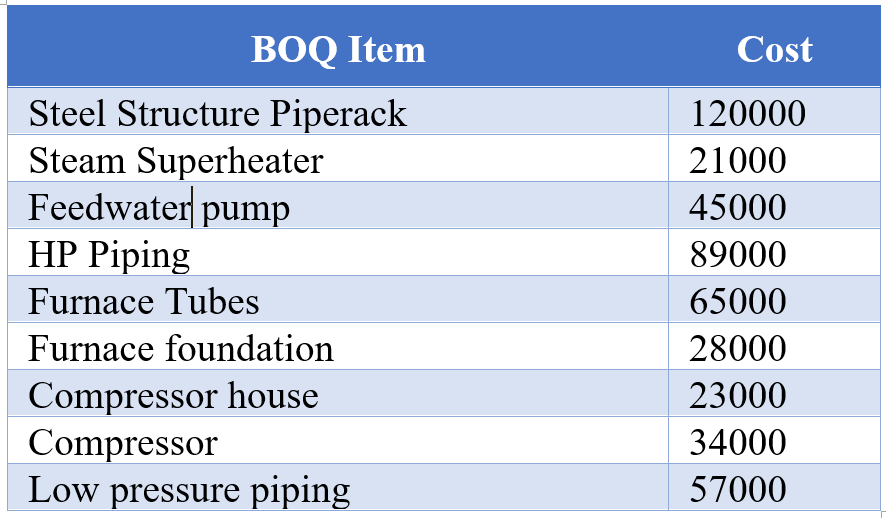

As we discussed on another article (here), on some projects, as per the contract, the contractor has to calculate the invoice value based on the earned progress and the client pays based on the verified progress. Therefore, the progresses and the weight values must be calculated and identified very carefully, otherwise it could cause many issues to the project. In this article, we will review an EPC project, where the client submitted a list as BOQ cost. Each cost item covers the E, P, C. then instructs the contractor to:

- In the schedule, load the cost precisely as the BOQ cost

- Monitor the construction activities only, therefore, only construction activities must be cost loaded.

- Include only the construction S-Curve and progress status in the weekly/monthly report

Then, project starts with Engineering and at end of the 1st month, the planner gets asked: What is the Engineering progress? He replies, as per the instruction, we don’t measure engineering progress. Next month, procurement starts and the planner gets asked about Engineering, procurement and overall progress? He replies in the similar vein! The PM says, does it means until construction there will be no progress reports? The planner says, that was the instruction and we all agreed! However, the planner feels that he is in the hotspot and must do something! He, immediately assigns a “Dummy Resources” to the engineering and procurement activities than reports the progress to PM! The PM seems happy and it continues like this.

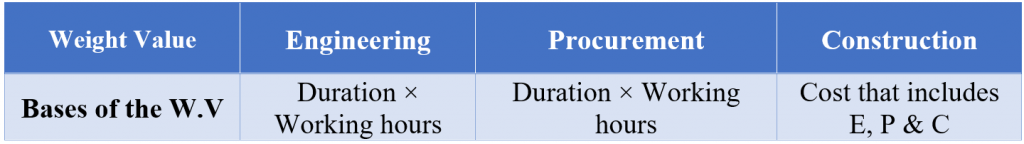

After a few months, the contractor’s cash flow become negative and stays so. The project gets delayed and the client asks for an increase in resources to catch up. Due to the negative cash flow the, contractor refuses and the project continues to suffer. The stress level goes too high and contractor’s team work long hours every day to identify what could be the issue!! So, what is wrong and why is the project in this mess? Nobody knows and nobody takes responsibility! The issues in the method for progress calculation which as a result, the contractor was not able to invoice the more accurate /enough amount. The progress calculation method that was set up by the planner implies, the Duration and Cost are combined! The dummy resource means Duration × Working hours / day. So, the engineering and procurement progresses are based on the duration and construction based on the Cost! (what an amalgam). Therefore, the contractor invoices were much lower than what he was paying to his team and the vendors and as a result the cash flow was negative.

Whose fault is it? 1st is the Client team that instructed to measure only the construction progress. Then the contractor’s management team that did not know the relationship between progress, weight value and invoice calculation. And more importantly the Planner that was trying to be out of hot spot and introduced the Dummy Resource. As stated, the argument around progress calculation and reporting never ends but the project team (both client and contractor) must know the PURPOSE for the setup of the system to serve the PURPOSE as best as possible otherwise it could easily be a death trap.

To audit and gap analysis of your Planning system and set up the integrated planning system contact us now.

Lincoln Ngindi

Posted at 12:21h, 07 DecemberGood read,