22 Nov Procurement: resource loading and progress

There seems to be no limit to incorrect planning procedures, for as we review some, we find weirder practises! The irony is that there is usually no report or analysis indicating the negative impact of these incorrect practises on project failure. Moreover, most of these practises are as per the instructions of a lead planner, client, and consultants. It gets accepted as a reliable source for status reporting and assisting the project team. In this article we will review, how the procurement activities get resource loaded and how it affects the project.

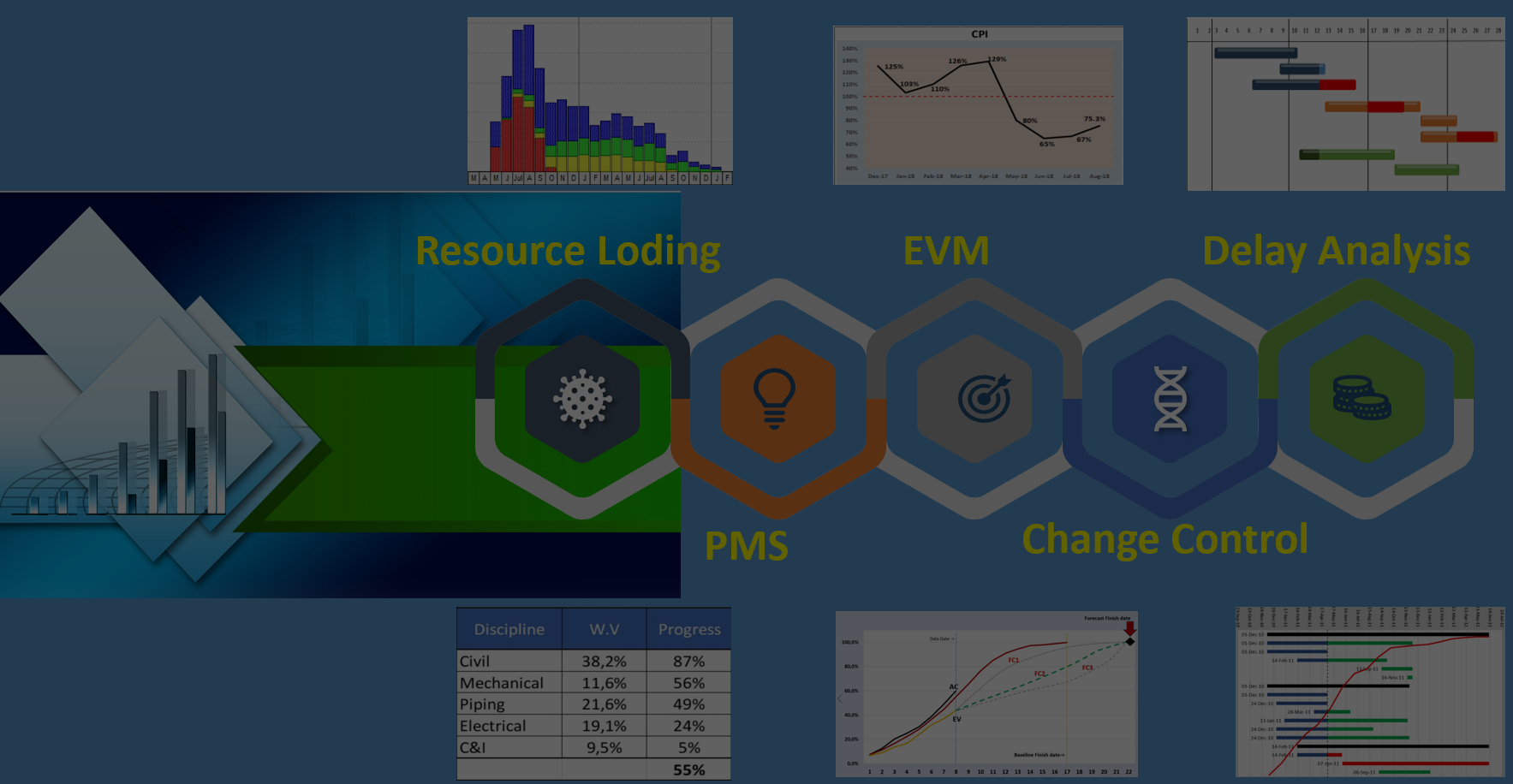

In an EPC project, the planner assigns resources to Engineering and construction activities. Then, he leaves the procurement activities with no resources. He presents it to client’s consultant, and the schedule gets rejected. The reason being that the procurement section is not resource loaded! The presented schedule to the client is as follows.

The planner responds by saying, there is no detail info (man-hour) available from the vendors, hence he could not assign resources. After back and forth movement, the client’s consultant realizes that vendors will not provide detail info for resource loading. Then he instructs the planner to assign one resource to all the procurement activities and update the budgeted units equal to duration × 8hrs!! Obviously, this is an incorrect practice and demonstrates that the client’s consultant does not know how to deal with procurement activities. The consultant’s argument for this practice is to have procurement progress and S-Curve, then use them for overall project progress and S-Curve!

In this project, the Engineering and construction budgeted units are based on the level of effort/work (man-hours) but procurement is based on the duration (duration × 8). How could man-hour and duration be combined to develop the overall S-Curve and progress?

On checking the contract, we realize that there are contractual weight values that are not used at all! The weight values of the EPC based on the data in the schedule is illustrated in the next screenshot dissimilar to contractual numbers!

This practice is being followed in many other scenarios as well:

- The budgeted units equal to duration

- Assign the same number (e.g. 2000) as budgeted units to all procurement activities regardless of the value, duration, etc.!

- Assign overall procurement cost value to the activities as per the duration of the activities!

- When the cost value of the packages is available then the cost values get assigned.

So, what will happen to the projects that use such practices? Who will take the blame for the incorrect system that misleads everybody on the project? The most important question is: How many PMs, management, client, stakeholders are conscious of these practices? Most likely none of them!!!

No Comments