05 May Cost Loading, Weight Value and Overall S-Curve

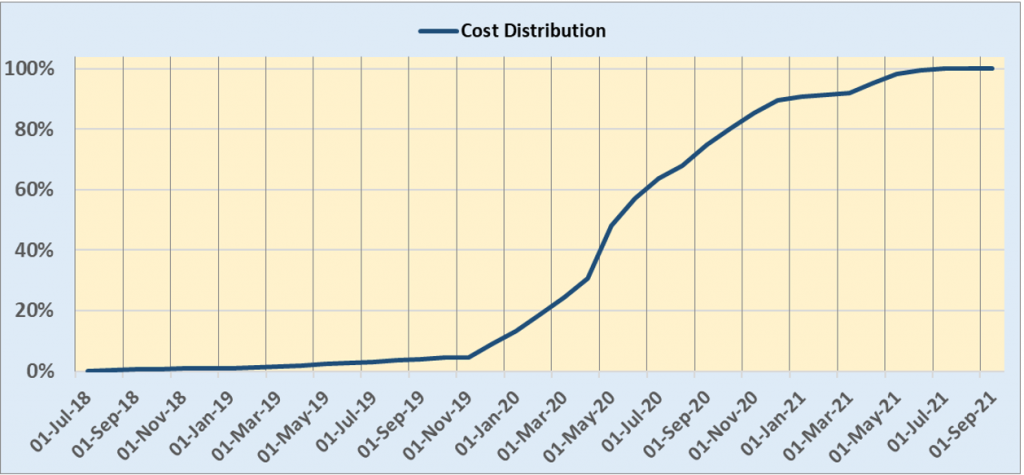

Schedule resource loading is one of the main challenges for many planners. On the contrary Cost loading of a Schedule as per the cost report (BOQ cost) is one of the easiest one’s. The process is simple; locate the activities in the Schedule that are related to each cost item, then enter/assign the cost value to the activity. If the cost report is in more detail, then the better. But if it is high level then there might be some challenges! In a $90 million project, the planner assigned the cost to the activities and the result is as follows:

As per the assignment, the weight value of Construction is 95% and Detail Engineering is 3.5%! However, when the contract and cost report gets reviewed, it could be found that:

- The Engineering cost of many activities is combined with Construction

- There were contractual weight values which were not used to develop the overall S-Curve, overall Progress

Due to No.1 above, the cost loading could not be acceptable which as a result directly affected the weight values, overall S-Curve and Progress! After completion of the Cost loading, 5 S-Curves were developed: Basic Design, Detail Design, Construction, Close Out and Overall. To develop the Overall S-Curve, the data was extracted directly from P6 and contractual weight values were ignored. The developed S-Curve is as follows:

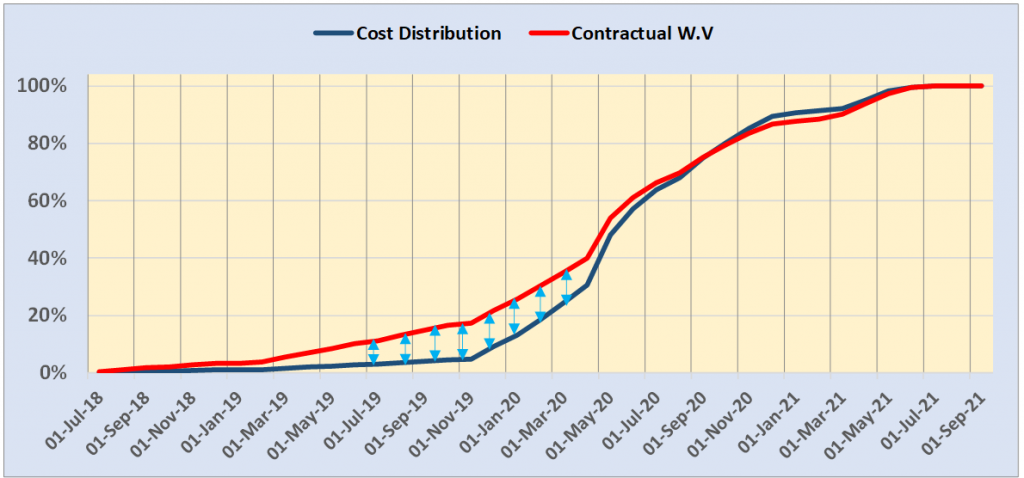

However, after using the contractual weight values, the overall chart gets changed and shows more than 12% gap in some periods.

It means, In Dec2019, if the Actual progress was 10%, based on the 1st chart the team was assuming they are running ahead of Schedule by about 5% whilst they were 10% behind schedule based in the weighted value chart!

So, would this project finish on time, within budget? Most-likely not and as per the recent report they are 9 months behind, which one of reasons could be incorrect planning system and reporting.

The Planning system MUST be able to support the PM and project manager instead of misleading. There are many variables in the planning and project control system that cannot be ignored or assume they are correct. For gap analysis of your project planning system contact us now. We will review and prepare a comprehensive report including how to fix the issues and gaps.

our email: info@khonopc.com

Dagne Mengiste

Posted at 07:18h, 03 JuneD

admin

Posted at 08:19h, 03 June??