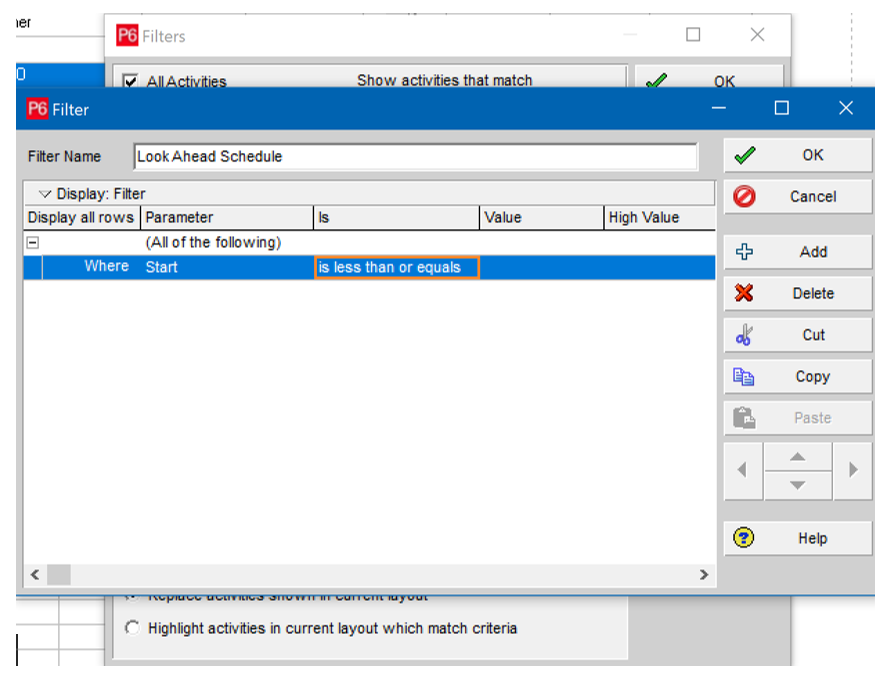

16 Mar Effective usage of the “Look Ahead Schedule”

Project Planners are frequently required to submit a “Look Ahead Schedule” to the Project team especially when the Project is running late. Also, when a Consultant has come on board with the hope of saving the Project. Theoretically, the Project team should work on the current week’s activities whilst also preparing for the upcoming weeks activities. As a result, again as per the theory, when the future activities reach the current state, then they should be ready to start/ finish as planned! However, this is not the experience that we have seen on many Projects. To most Planners, a look ahead schedule is a filtering of activities from the Schedule and for the Project team that should be sufficient!

The Look ahead Schedule, is sometimes a few activities whilst at times it could comprise countless number of activities, dependent on the schedule level of detail and the number of activities. Usually, at the early days, the Project team tries to utilize it and requests weekly updates. On the contrary, they soon start ignoring it partly to following reasons:

- When it has fewer activities, the Project team soon realizes that there are far more activities on site compared to what is reflected on the Schedule.

- If it is several pages then the site team realize that the dates, logic, priorities do not match the site and is like the schedule is for another project. As a result, they abandon it!

So, how to use the Look Ahead Schedule effectively?

In order to implement the look ahead concept effectively, we should know that:

- The site condition is dynamic therefore, it should be flexible to manage it

- It is not necessarily a simple filtering exercise of the activities.

- It requires a database/list of the activities, sometimes very detail

- It might require a separate planning team to run with it

- It requires procedure, process charts, data collection process, roles and responsibility, training, etc

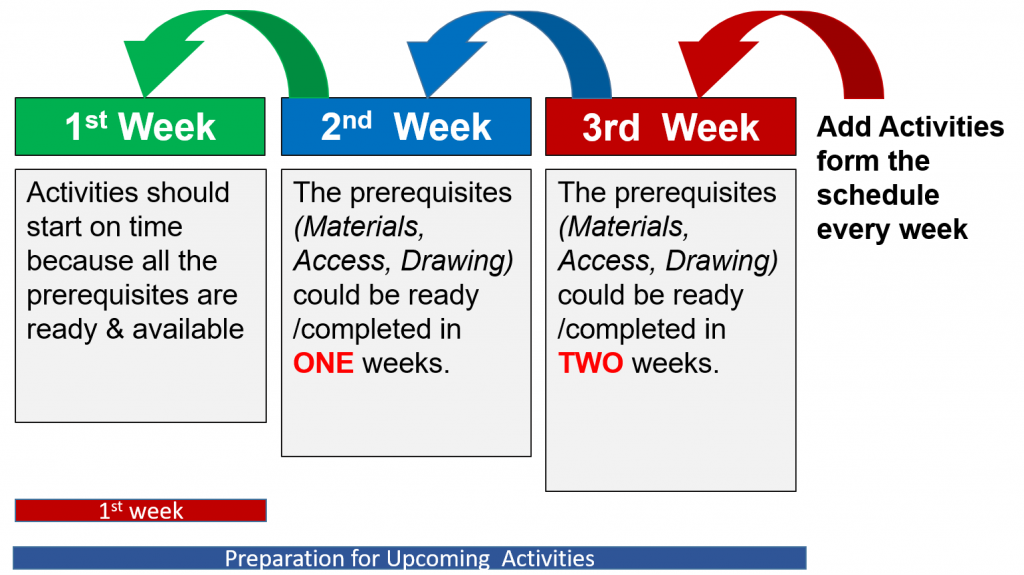

The image below is a typical and high level process that illustrates how the activities have to be checked, worked, prepared before they come into the current week.

As the image shows, the process is dynamic and requires undertaking in two different layers. First layer is the current week’s activities and the 2nd layer is working on the upcoming activities. These 2 layers run in parallel.

When the Look ahead concept gets implemented correctly then the project experiences massive improvement in production rate, date recovery and cost saving.

Is your project late and requires improvements in production rate and productivity rate?

Do you want to implement the look ahead technique to save time and cost of the project?

If your answer is Yes, then contact us now.: info@khonopc.com. We will implement the above technique with all other requirements.

No Comments