17 May What is the purpose of the Integrated Master Schedule?

Failure in Interface management of construction projects could cause significant cost overrun, delay and easily collapse any multi-contracting project. Herein is an example of what we once witnessed.

A couple of years ago, we received an urgent request to develop a new Integrated Baseline Schedule for a multi-billion dollars’ Project in one week only (is it feasible?!). On the 1st site visit, we were invited to a meeting to observe how the weekly progress meetings are running. Surprisingly, In the meeting both client/PMC and contractor had their lawyers and senior contract managers present. But why were the lawyers present in the weekly progress meeting? We soon found out, why?

It was a multi-contract Project and the PMC was responsible for developing the Integrated Master Schedule (IMS). When the IMS was developed, the PMC team were assuming that it will be a simple high Level Schedule to report the Project’s status to the Client. There were no thought processes for interface management. In early days of the Project there were no issues with interface management because mainly civil works were in progress! However, during MEIP installation, the interface management became a monster of an issue. The PMC team was trying to extract some dates, as interface, from the Contractor’s Schedule, review it with the team then share with each contractor. Contractors were trying to exploit the situation to make more claims by playing around with the logics, changing durations, adding/ deleting activities, etc. therefore, nobody could give any date about when an interface will be available for another contractor to continue the works. This was the reason for having lawyers in the progress review meetings!!

After our findings report, the PMC contracted 2 consultants to develop a new IMS. The 1st one was so called global leading project management consultant and 2nd one was a local leading consultant!! After 9 months both these leading consultants failed especially the 1st one who claimed that they developed 87% healthy schedule! But when we deleted the 2 placeholder milestones, most of the activities sat on the data date!! There are 4 practices for IMS development:

1- The planner, copies all the schedule in one EPS or one file. Then opens them together. No or only few links among the schedules (very simple and easy)!! For updating, the updated schedules get copied in a new EPS / file. Or the planner tries to update them automatically!

2- This one is almost same as the No.1 but the planner tries to add more links among the schedules. The process of adding more links could take several weeks but generally it does not get done systematically. Therefore, for every update, the planner has no choice either update automatically or redo the linking again and again!!

3- The planner develops a separate higher level schedule then updates it manually. This schedule, might accidentally have some activities that are related to some interfaces, same as project above.

4- The planner creates a Milestone schedule then links the activities through this schedule. Updating is still a challenge either could be done automatically or manually. For manual update, No. of planners would be required.

So:

- How did you develop your IMS?

- Does it support the project effectively?

- Or you are struggling or your P6 database has been corrupted several times already?

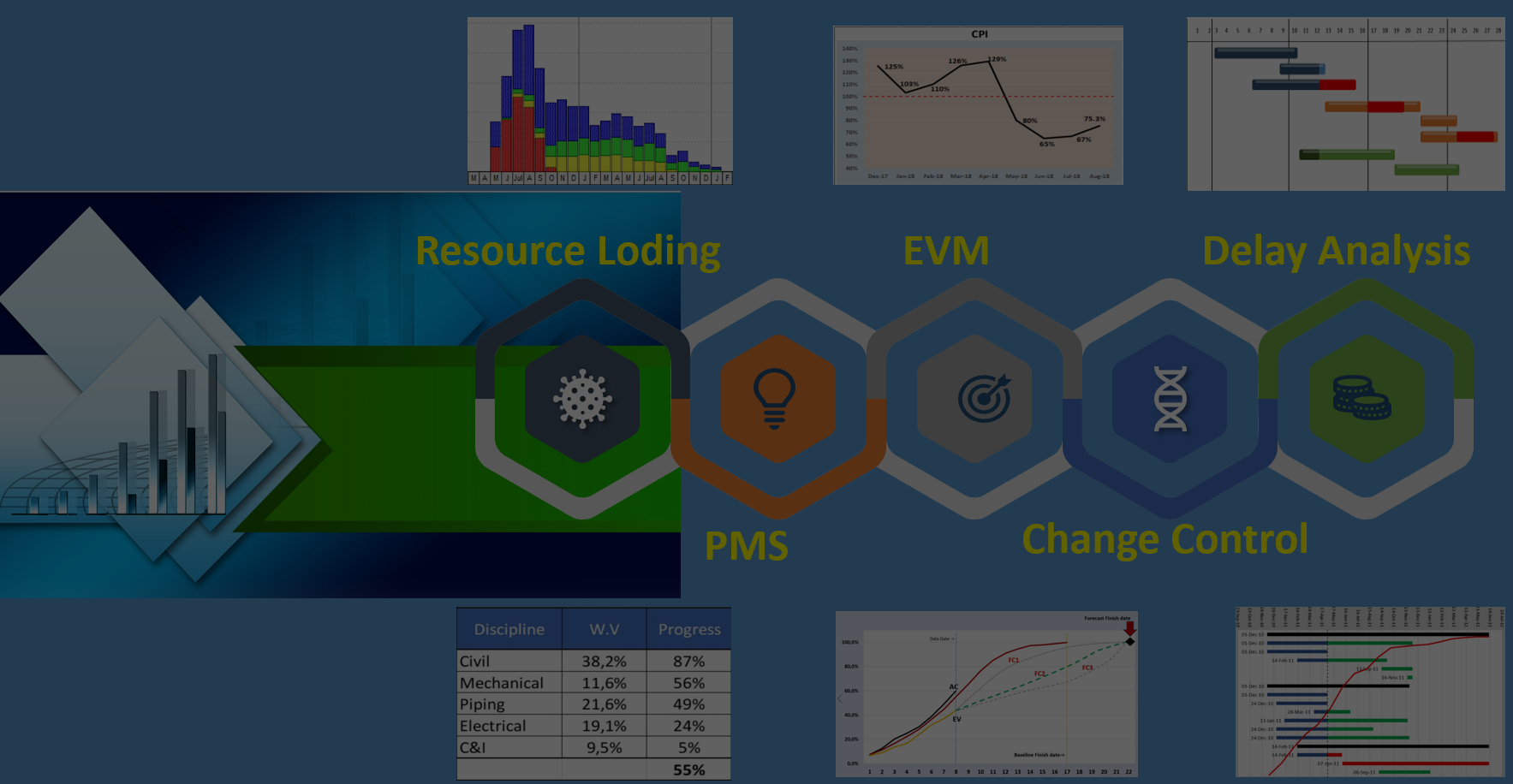

Development of IMS is not easy and at the 1st step, the team MUST know what the purpose is and how it could be achieved. Also, it does not mean that the contractors schedule has to be redeveloped as part of the IMS! If you want to develop an effective IMS to assist in interface management and reduce costs, then contact us now: info@khonopc.com

No Comments